Metallography & Microscopy

Metallographic evaluation shows details beyond human vision. Advanced methods and powerful microscopes are essential for analyzing part failures and material processing.

SMS Labs has a highly advanced metallographic lab with years of experience analyzing complex alloys, from ancient artifacts to aerospace super alloys. Their careful procedures are tailored for each alloy type, condition, and form.

Request a Quote for Metallography & Microscopy

Services Include:

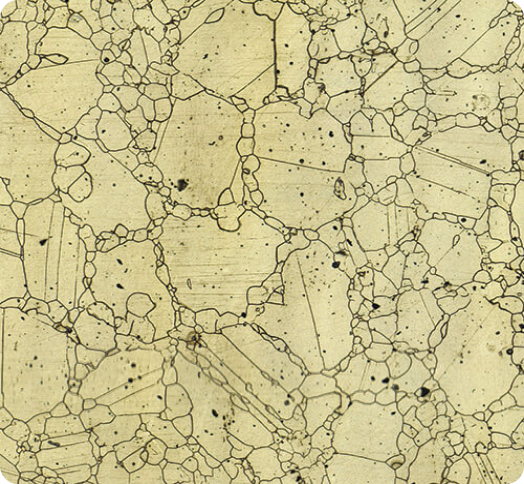

- Grain Size (ASTM E112)

Grain size analysis, as outlined in ASTM E112, is a standardized method used to determine the average grain size of metals and alloys. This process involves comparing prepared metallographic specimens to standardized comparison charts or utilizing image analysis techniques to measure grain dimensions accurately. Grain size plays a critical role in the mechanical properties of a material—such as strength, toughness, and fatigue resistance—making this analysis essential for quality control, material selection, and failure investigations.

By following ASTM E112, laboratories and manufacturers ensure consistency, repeatability, and compliance with industry standards. Whether performed through visual comparison, the intercept method, or advanced digital imaging, grain size analysis provides valuable insight into the microstructure of materials, helping industries maintain performance, reliability, and regulatory standards.

- Inclusion Rating (ASTM E45)

Inclusion rating as defined by ASTM E45, is a standardized method used to evaluate the type, size, and frequency of nonmetallic inclusions in steel. These inclusions—such as oxides, sulfides, or silicates—are microscopic particles that can form during steelmaking and may influence the material’s mechanical performance, machinability, and overall quality. By carefully examining polished samples under a microscope and comparing them to reference charts, laboratories can assign a rating that reflects the cleanliness of the steel.

Following ASTM E45 ensures a consistent and reliable approach to assessing steel quality across industries. Inclusion rating is widely used for material certification, process control, and failure analysis, helping manufacturers and end users ensure that steels meet the demanding standards of aerospace, automotive, energy, and other critical applications.

- Carburization / Decarburization (ASTM E1077)

Carburization and decarburization analysis, as outlined in ASTM E1077, is a standardized method used to evaluate changes in the carbon content of steel surfaces during heat treatment or processing. Carburization refers to an increase in surface carbon, while decarburization is the loss of carbon from the surface. Both conditions can significantly impact material properties such as hardness, wear resistance, fatigue strength, and dimensional stability.

ASTM E1077 provides reliable procedures for detecting, measuring, and rating the depth of these altered surface layers through microscopic examination. By following this standard, manufacturers and laboratories can ensure accurate assessment of heat-treated steels, supporting quality control, process optimization, and compliance with customer and industry requirements.

- Case Depth/Heat Treat Evaluation (Industry Specifications)

Case depth and heat treat evaluations are critical processes used to verify the effectiveness of heat treatment in steels and alloys. Case depth refers to the thickness of the hardened surface layer produced by processes such as carburizing, nitriding, or induction hardening, which improve wear resistance and fatigue strength while maintaining a tough core. Evaluating case depth ensures that components meet performance requirements for durability, load-bearing capacity, and service life.

Many industries—including aerospace, automotive, energy, and heavy equipment—require stringent heat treat evaluations to confirm hardness profiles, microstructural changes, and conformance to specifications. These evaluations are typically performed through microscopic examination, hardness traverses, or both, providing reliable data to validate heat treatment processes. By meeting these standards, manufacturers ensure consistent product quality, regulatory compliance, and confidence in critical applications.

- Laser Recast / Non-Traditional Machining Evaluation

Laser recast analysis and non-traditional machining evaluations focus on assessing the surface integrity of components manufactured using advanced processes such as laser cutting, EDM (electrical discharge machining), and other non-conventional methods. These processes can leave behind a “recast layer,” microcracks, heat-affected zones, or surface irregularities that may influence part performance, fatigue resistance, and long-term reliability. Evaluating these conditions is essential for ensuring the integrity of precision components used in demanding applications.

Industries such as aerospace, medical device, automotive, and energy often require strict evaluations of machined surfaces to confirm compliance with customer specifications and regulatory standards. Through microscopic examination, hardness testing, and metallographic evaluation, laboratories can detect and characterize recast layers or machining-induced damage. These assessments provide valuable data to validate manufacturing processes, enhance quality control, and ensure that critical parts perform safely and consistently in service.

- Porosity Measurement

Porosity analysis and measurement are essential for evaluating the quality and integrity of metals, alloys, and advanced materials such as castings, welds, and additive manufactured components. Porosity refers to voids, gas pockets, or shrinkage cavities that form during solidification or processing, which can reduce strength, toughness, fatigue life, and overall reliability. By examining polished samples microscopically or through image analysis, laboratories can determine the size, shape, distribution, and volume fraction of porosity present in a material.

Industries including aerospace, automotive, medical device, and energy rely on porosity evaluations to ensure components meet stringent performance and safety requirements. Accurate porosity measurements support process control, defect prevention, and compliance with customer and industry standards, providing confidence that materials will perform reliably in critical applications.

- Intergranular Attack (ASTM F2111)

Intergranular attack (IGA) analysis is used to evaluate the susceptibility of metals, particularly stainless steels and nickel alloys, to corrosion that occurs preferentially along grain boundaries. This localized form of corrosion can significantly weaken materials without obvious surface damage, making it a critical concern in industries where reliability and safety are paramount. Metallographic examination, often combined with standardized test methods, helps identify the presence and extent of intergranular attack and its impact on microstructure.

Industries such as aerospace, chemical processing, power generation, and oil and gas require intergranular corrosion evaluations to ensure materials meet stringent service requirements. By detecting early signs of attack and verifying resistance after heat treatment or welding, these analyses support quality control, process validation, and long-term performance of critical components.

- Carbide Formation/Precipitation

Carbide formation and precipitation analysis is a metallurgical evaluation used to study how carbides develop and distribute within metals and alloys during manufacturing or heat treatment. Carbides—compounds of carbon with elements such as chromium, tungsten, or vanadium—can strengthen materials, enhance wear resistance, and improve high-temperature performance when properly controlled. However, excessive or improperly distributed carbides may reduce toughness, promote intergranular corrosion, or impair fatigue resistance.

By examining polished and etched specimens microscopically, laboratories can assess carbide type, size, morphology, and distribution to ensure they align with material specifications and performance requirements. Industries such as aerospace, automotive, tooling, and energy rely on carbide analysis to validate processing methods, optimize heat treatments, and confirm the durability and reliability of critical components.

- Phase segmentation

Phase segmentation analysis is a metallographic technique used to identify, quantify, and characterize the different phases present within a metal, alloy, or engineered material. Phases such as ferrite, austenite, martensite, or secondary constituents directly influence mechanical properties like strength, toughness, corrosion resistance, and wear performance. By applying advanced imaging and digital analysis, laboratories can accurately measure the distribution, volume fraction, and morphology of each phase, providing critical insight into how processing and heat treatment affect material behavior.

Industries including aerospace, automotive, energy, and additive manufacturing rely on phase segmentation to validate material design, optimize processing routes, and ensure compliance with demanding specifications. This analysis supports quality assurance, research and development, and failure investigations by delivering precise microstructural data that links material structure to performance.

- Weld Evaluation (Industry Specifications)

Weld analysis is a critical process for evaluating the quality, integrity, and performance of welded joints across a wide range of materials and applications. Through techniques such as visual inspection, metallographic examination, hardness testing, and failure analysis, weld evaluations can identify issues like cracks, porosity, lack of fusion, or heat-affected zone irregularities. These assessments help ensure that welds meet industry standards, customer specifications, and the demanding requirements of safety-critical applications.

At our laboratory, weld evaluations are performed by certified weld inspectors (CWIs) with the expertise to provide accurate, reliable, and standards-compliant results. This certification ensures that every inspection is carried out to the highest level of professionalism, giving our clients confidence in the performance and reliability of their welded components. Whether for aerospace, automotive, energy, construction, or heavy equipment industries, our weld analysis services support quality control, process validation, and long-term structural integrity.

- Plating / Coating Evaluation

Plating and coating evaluations are essential for assessing the quality, uniformity, and durability of protective or functional surface treatments applied to metals and alloys. These evaluations examine parameters such as coating thickness, adhesion, microstructure, porosity, and potential defects to ensure the plating or coating meets performance specifications. Proper analysis helps prevent premature wear, corrosion, or failure, which is critical for components used in demanding industrial, aerospace, automotive, and energy applications.

By combining metallographic techniques, microscopy, and advanced measurement tools, our laboratory can provide precise and reliable assessments of plated or coated surfaces. These evaluations support quality control, process optimization, and compliance with industry standards, giving manufacturers confidence that their components will perform reliably in service and maintain long-term durability.

- Thickness Measurement

Thickness measurements are a fundamental aspect of material evaluation, used to determine the precise dimensions of coatings, platings, and base materials. Accurate measurement of thickness ensures that components meet design specifications, performance requirements, and industry standards. These assessments are critical for controlling material properties, verifying protective coatings, and preventing failures due to under- or over-application of surface treatments.

Our laboratory utilizes advanced techniques, including microscopic cross-section analysis, non-destructive methods, and precision instrumentation, to deliver reliable and repeatable thickness measurements. These evaluations support quality control, process verification, and compliance with customer and industry specifications, providing confidence that materials and components will perform as intended in demanding applications.

Microscopy Equipment:

- Eight (8) Light optical microscopes (upright and inverted) with digital image acquisition and advanced analysis software.

- Seven (7) Stereo microscopes with digital image acquisition and advanced analysis software.

- Two (2) Keyence VHX digital microscopes with 3D image stitching and image analysis up to 5000x magnification

- Two (2) Hitachi Scanning Electron Microscopes with Light Element Detectors (EDS).

- Six (6) Portable field microscopes

- Four (4) Presi Automatic 12” Polishers

- Two (2) Presi Manual 8-12” Polishers

- Four (4) Presi Automatic Hot Mounting Presses

- Four (4) Abrasive Cut Off Machines 6-12” Capacity

- One (1) Kalamazoo Metal Cutting Band Saw

- Eleven (11) Light optical Microscopes upright and inverted with digital image acquisition and advanced analysis software.

ISO/NADCAP/GE/PW Accredited

Certified to deliver precise, internationally recognized results.

Fast Turnaround Times

Quick, efficient processing to keep your manufacturing timelines on track.

Experience Matters

Our team of seasoned engineers and techs bring decades of hands-on industry knowledge.

Detailed & Defensible Reports

Clear, illustrated reports with actionable insights and data integrity.

Why choose us?

Trusted by leading industry professionals for reliable result, expert analysis and unmatched quality of service.

About SMS Labs

Sturbridge Metallurgical Services was founded in 1990 in Sturbridge, MA, by President, Courtney Grimes. Our small, independent testing lab has outgrown three locations through the years, before settling into our current home at 8 Picker Road in Sturbridge, Massachusetts. Our lab offers a complete range of materials testing and analysis services, and we've expanded into sales of a full line of metallographic equipment and supplies.

Learn more